Tube Mill Software (TMS) is a custom ERP software system that fits into Tube Mills, Roll Formers and other Steel Rolling Mills. In 2014, P.S. Data launched TMS after closely working with a Tube Mill to understand the industry specific needs. As we are continuing to add more roll formers and tube mills, TMS will continue to be the industries best ERP software system available for this segment. If you are a Tube Mill, Roll Former or own Steel Rolling Mills with or without shop floor automation requirements and are ready for an industry specific software system, take a look at a demonstration today.

Features & Functionalities

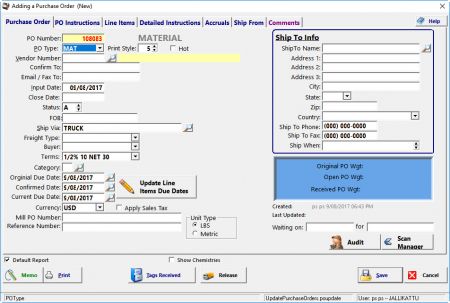

| Purchase Orders |

| · Material, Various outside processing and other PO processing |

| · Special features for Steel importers, On Water inventory tracking etc |

| · PO Templates for Repeat orders |

| · Support for Blanket PO management, CRU Pricing management |

| · Projection number tracking |

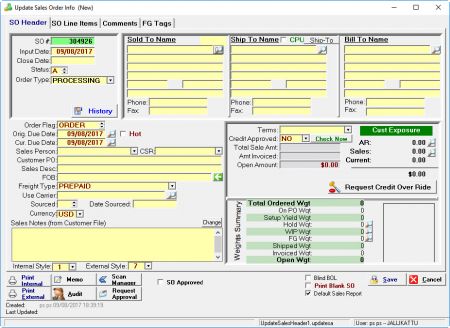

| Sales Orders |

| · Sales order for Material sale and toll processing support |

| · Support for Blanket Sales Order management |

| · Customer specific shipment Reports |

| · Complete sales commission calculation, accrual, Payment automation |

| · Automatic credit limit controls and Override approval options |

| · By Customer By Production or Service based extremely detail pricing matrix setup |

| · Program based pricing matrix setup for processing, storage |

| · Pricing based of a matrix, min weight, gage thickness, and many, many, many more! |

| · Sales Inquiry management, Quote system with custom templates |

| · Release processing and traceability. Supports Freight rate lookup auto maintenance. |

| · Traffic management system for daily scheduled deliveries |

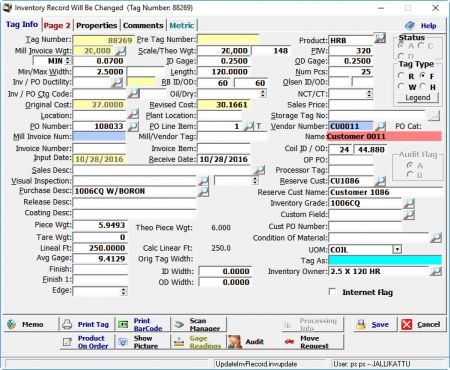

| Inventory Management Control |

| · Complete Owner Inventory Control – with extremely detail cost buckets |

| · All Inventory costing reports reconciles to General Ledger |

| · Product hierarchy, Part Number, Item code definition |

| · Powerful inventory search and filtering option. |

| · Onsite and Offsite Inventory Control |

| · Complete Customer Owned Inventory Control |

| · Physical Inventory Audit functionality |

| · Inventory cost controls like Cost Average, Markdown, Write-down etc |

| · Material test reports – Tracking, Validation, EDI Automation etc |

| · Intercompany material transfers and payment handling |

| · Inventory move request automation |

| · Inventory Quality control with Hold / Defect / Damage Code / Status code controls. |

| Invoice System |

| · Complete control over Owner material invoicing |

| · Sending invoices to customers thru automatic email or EDI |

| · Exact profit margin by invoice by tag. |

| Integrated Accounting Package |

| · General Ledger Complete Integration instantly. No double entry. |

| · Accrual based accounting system, Cost accounting, Variance analysis |

| · Accounts Payable |

| o Several check styles and support for MICR checks, Batch check writing and Positive Pay |

| o Sending Remittance Notes |

| o Importing payables via excel / EDI, reducing data entry and errors |

| o Prepayments by PO control |

| o Customer, Mill and Processing Claim Management |

| o Support Credit card statements, Check Register, Contra, Accrual vs Payable Variance Control. |

| · Accounts Receivable |

| o All types of deposits including Prepayment, Overpayment, Apply Mass invoices |

| o Send monthly customer statements |

| o Collection call tracking, Follow-up, AR Overdue alerts |

| · Financial Reporting |

| o Complete financial reporting functionality – Balance Sheet, Income Statement, Trial Balance etc |

| o Company Management Report for Business Status on ONE Page |

| o Special banking reports like Borrowing base report, cashflow reports etc |

| o Customized Financial Reporting |

| o Special calendars for 5-4-4-week periods. Special Fiscal year configurations |

| Shipping, Receiving |

| · Real-Time Shipping and Receiving Schedule |

| · Barcode Capabilities, AIAG Labels |

| · Custom Bill of Lading by Customer and Export Customs paperwork generation |

| · On Shipment automatically sending BOLs to customers, Ship To locations with Driver Signature |

| · Optional driver self-check-in kiosk |

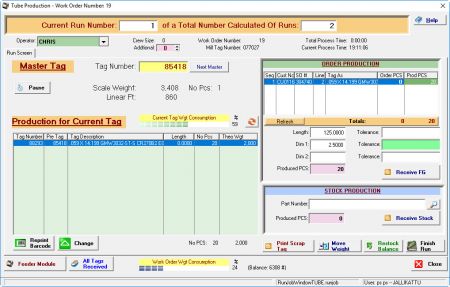

| Production |

| · Work Order and Toll Order Processing. Run job, Weigh station and packaging screens. |

| · Real-Time Production Planning and Scheduling |

| · Barcode Capabilities, AIAG Labels |

| · Integration with External systems like Scales, Electronic width/gage devices, AGT gagers etc |

| · Customized Handle held application supporting Material moves, Inspection, Inventory Audits etc. |

| · Shift Production status display setup for LED TV displays at the shop floor |

| · Machine Schedules for each machine |

| o Set priority on work orders |

| o Automatic Work Log and Production Stops reporting |

| o Tool configuration and Daily calibration |

| o Scheduled Maintenance |

| o Maintenance requests from Machine Operators |

| o Maintenance requests work flow with cost control |

| ISO Module |

| · Integrated ISO Complains, Corrective Action, 5 Whys |

| · ISO Related record keeping |

| All Reports export out to PDF and Excel as needed |

| Powerful reporting platform for custom reports, Business Intelligence for KPIs and Statistical Analysis |

| Complete Audit Log for all user updates |

| Scan documents & Drag and drop attachment to all records |

| Multi Business Location Support |

| Multi Division Support |

| Multi Companies Support – Different legal entities, Logistics company, Properties company etc |

| Multi-Currency Support |

| Multi Lingual Support |

| Data Security control to Module / Screen / Fields at User level or Group level |

| EDI ready, supports: |

| o 856 – Advanced Shipment Notice |

| o 863 – Test Report / Chemistries |

| o 810 – Invoice |

| o 820 – Remittance Advice |

| o 850 – Purchase Orders |

| o 997 – Functional Acknowledgments |

| Platform |

| · Microsoft Windows PC platforms. All currently supported operating systems. |

| · Microsoft SQL Database with powerful reporting and Business Intelligence features |

| Hand held application available for Smart Phones |

| Internet Add-on options to you existing websites |

| o Show Owner inventory for sale tags with pictures and chemistry |